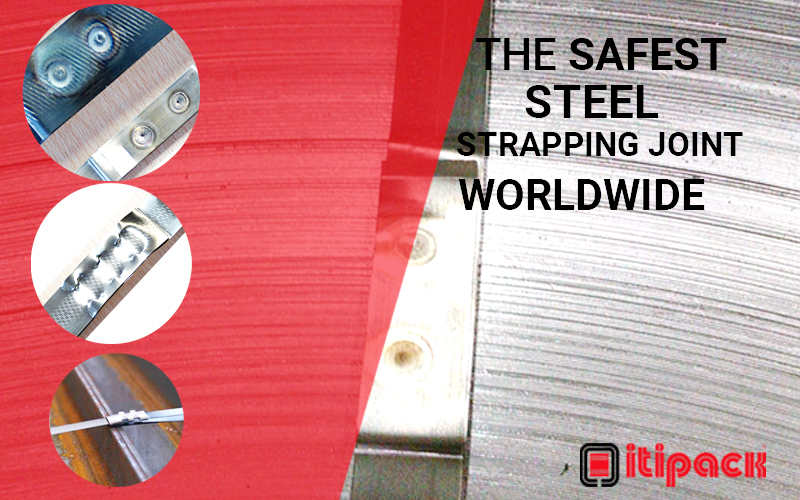

THE SAFEST STEEL STRAPPING JOINT WORLDWIDE

In this article we would like to give you an overview of the different types of joints for the application with steel strapping for metal Industry.

There are 3 types of joint most used:

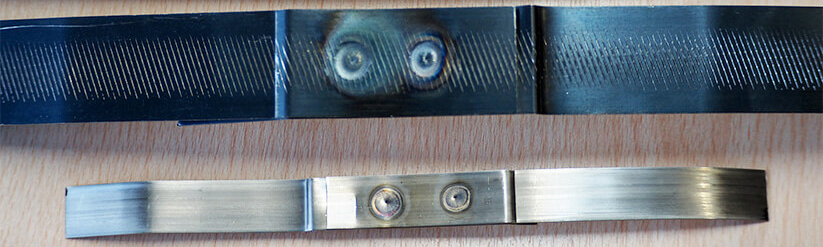

-The Seal Joint

This is the oldest sealing type.

The lower and the upper steel strap are being crimped mechanically two or four times. The joint efficiency is approx. 70-75% of the strap breaking load.

Advantages:

+suitable for strapping of small surfaces

Disadvantages:

-additional material “seal” necessary

-less joint efficiency in comparison to all other joint types

-the steel strap is being damaged at both sides due to the crimping

-decreased joint efficiency due to mechanical wearing of the crimping unit

-The No-Seal-Joint or Punched Joint

The safety joint is formed by successive punching.

The strap in the joint area is almost tension free.

The punched joint of the strapping heads effectively prevents the strapping joint from breaking (=re-opening).

The joint efficiency is approx. 85% of the strap breaking load.

Advantages:

+higher joint efficiency in comparison to the Seal-Joint

+no additional “material” necessary

+optical cleary visible joint

Disadvantages:

-the steel strap is being damaged mechanically due to the punching

-decreasing joint efficiency due to mechanical wearing of the cutting unit

-The TIG-Weld-Joint

this is based on the TIG welding process. It is today the safest sealing for steel strapping worldwide. The strapping heads operate using the “TIG” (“Tungsten-Inert-Gas”) welding technology with a non melting Tungsten electrode and inert gas.

The welded joint is created without contact by an electric arc between the electrode and the strap under inert gas.

As a result of this process, the metal melts and the two overlapping straps are joined. The joint efficiency is approx. 90% of the breaking load of the strap.

Advantages:

+suitable to strap small packages

+highest joint efficiency in comparison to other joint types

+guaranteed minimum joint efficiency

+reduction of strap cross section = reduction of material costs

+cost efficient joint building process

+clearly visible and recognizable joint

+AAR approved

+weld-joint is the most demanded strapping joint technology in the eteel and non-ferrous industries when it is coming to fully automatic applications-worldwide

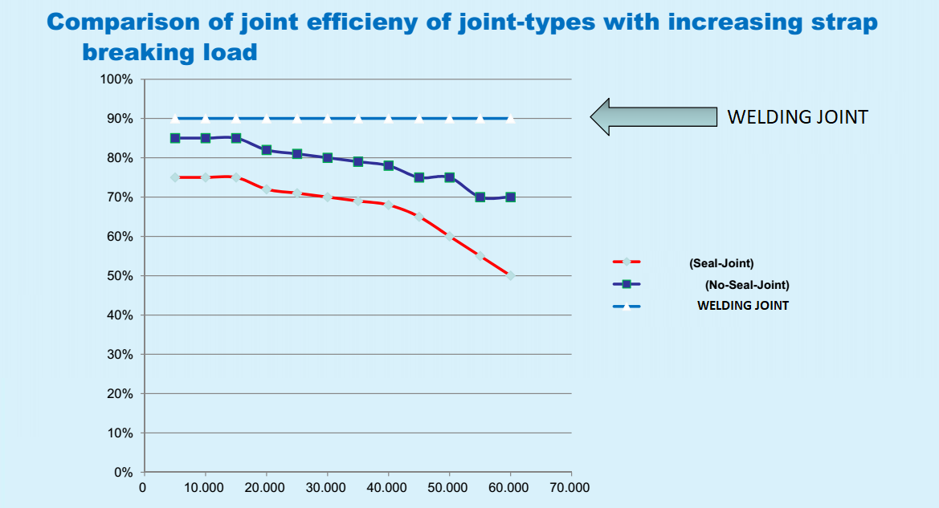

Here a clear comparison of joint efficiency

Curious to know more?

We realized a quick infographic about comparison between these 3 solutions

HERE

Just a LITTLE detail …

our welding technology is not by electrical resistance!

We use the most effective welding technology on the market: CONTACTLESS TIG WELDING.